Discover how BH Global Corporation Ltd leveraged Simplr’s Warehouse Management System to streamline warehouse operations and achieve remarkable efficiency gains.

Impact Achieved

Stock Accuracy

Increase in Warehouse Efficiency

into Inventory Status

“Simplr made all impossible became possible. Because of Simplr WMS we achieved 100% stock accuracy and helped us to increase overall warehouse efficiency.”

Logistics Director

BH Global Corporation Ltd,

BH Global Corporation Ltd, Singapore

Industry: Appliances, Electrical, and Electronics Manufacturing

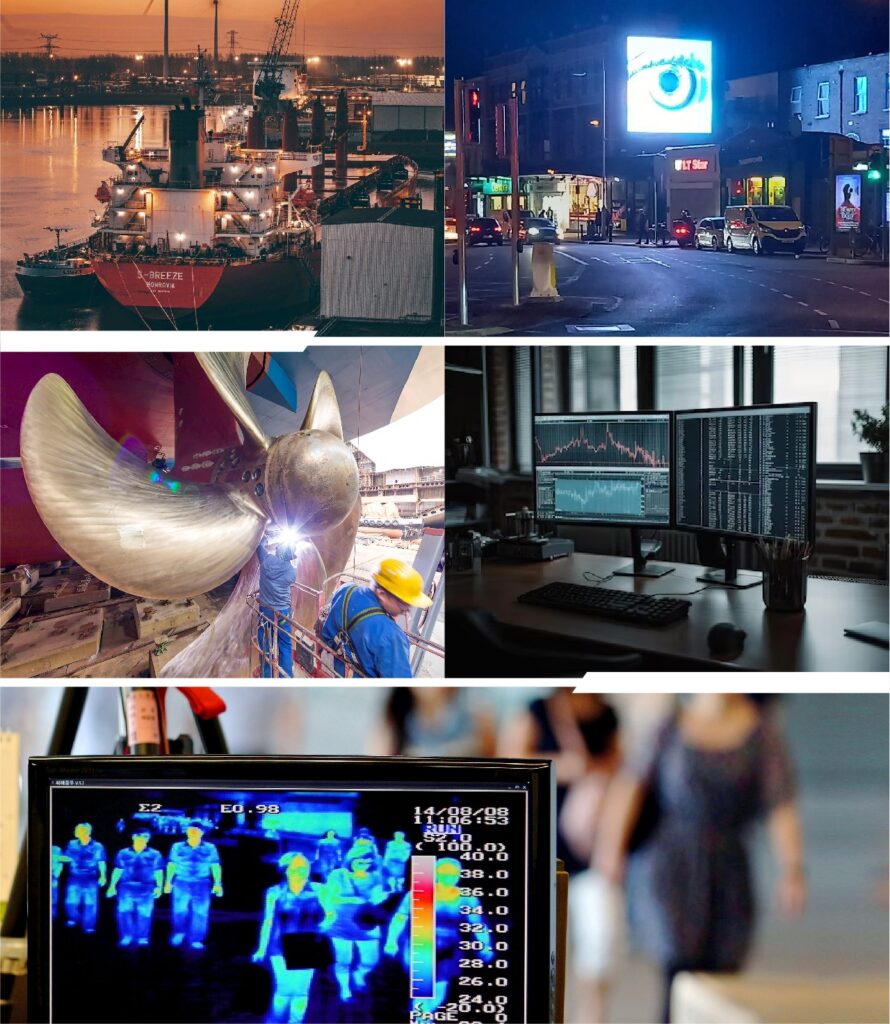

From humble beginnings, BH Global Corporation Ltd (SGX: BQN) has grown and evolved itself to provide a comprehensive suite of solutions in varying fields. BH Global is focused on continual transformation and improvement through sustainable Digitalisation, Electrification, and Environmental initiatives. These initiatives value-add to our products and services by providing better solutions to our clients. Providing solution for

- Marine and Offshore

- Green LED

- Integrated Engineering

- Cyber Security

- Infrared and Thermal Sensing Technology

Employees

Annual Revenue

Challenges Faced by BH Global

Need for Better Inventory Management

Manual Verification of Inventory Figures

Manual Warehouse Operations Resulting in Errors

High Level of Stock Accuracy Required

Significant Human Errors in Operations

Inefficient Warehouse Operations

Lack of Visibility into Warehouse Processes

Solutions Deployed

Simplr Warehouse Management System (WMS)

Implemented a Warehouse Management System to automate and optimize warehouse operations, from receiving and put-away to picking, packing, and shipping.

Schedule a free consultation to learn more!

Solutions Deployed

Warehouse Management System

Implemented a Warehouse Management System to automate and optimize warehouse operations, from receiving and put-away to picking, packing, and shipping.